Choosing the Right Retorting System for Your Containers and Products: A Comprehensive Guide

For manufacturers of Acidified (AF) and Low-Acid Canned Foods (LACF), choosing the right retort system is not only about preserving product quality—it is about meeting stringent regulatory requirements, ensuring consumer safety, and staying competitive in a rapidly changing marketplace.

Choosing the Right Retorting System for Your Containers and Products: A Comprehensive Guide

For manufacturers of Acidified (AF) and Low-Acid Canned Foods (LACF), choosing the right retort system is not only about preserving product quality—it is about meeting stringent regulatory requirements, ensuring consumer safety, and staying competitive in a rapidly changing marketplace.

Why Choosing the Right Retort Matters

The choice of retort system directly influences product safety, package durability, and consumer acceptance. A retort that is poorly matched to the container may result in packaging failures such as paneling, delamination, or seal failures, all of which compromise sterility and shelf life. Beyond safety, the wrong system may also affect product quality by overcooking, underprocessing, or creating uneven thermal distribution. This means that texture, flavor, and nutrition may all be compromised.

From an operational standpoint, the choice of retort determines throughput, flexibility in handling multiple product lines, and the long-term sustainability of the process. Batch retorts are widely preferred for their ability to handle diverse product and container combinations. Continuous sterilizers, though effective for very high-volume operations such as canned vegetables or pet food, require large capital investments and are less adaptable to innovative packaging formats. For this reason, batch retorts remain the system of choice for many modern processors.

Types of Retort Systems

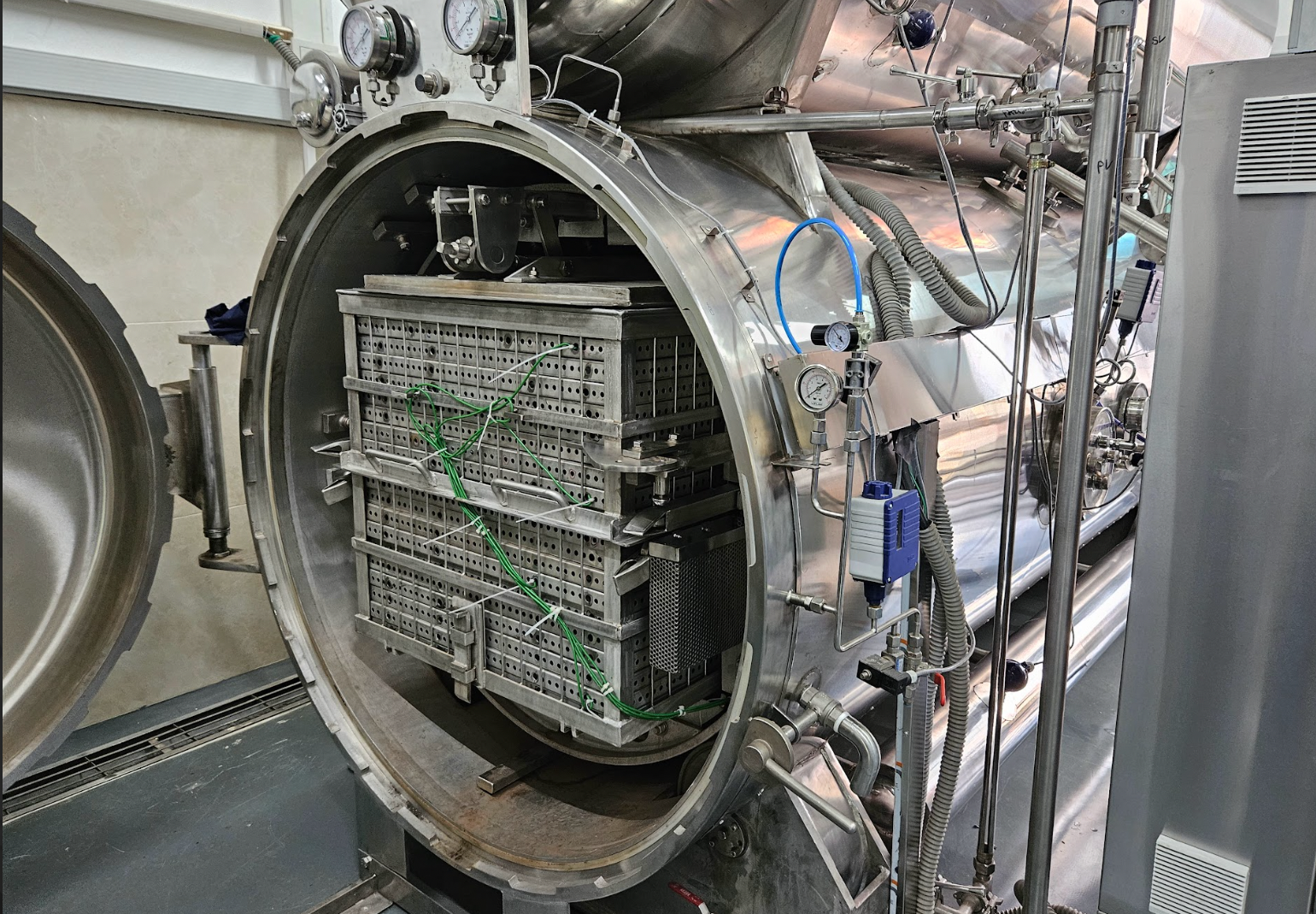

Water Immersion Retorts

Water immersion retorts are among the most established thermal processing systems. They can be designed in vertical or horizontal orientations, and their effectiveness comes from completely submerging the product load in heated water. Vertical immersion retorts are often used for cylindrical containers such as bottles and jars, where the upright geometry allows for even coverage. Horizontal immersion retorts, on the other hand, are more suitable for trays, pouches, and flat metal cans, since the containers can be arranged in layers that are completely immersed.

One of the strengths of water immersion retorts lies in their ability to create stable pressure conditions around the container, protecting delicate packaging formats during processing. However, maintaining uniform heating across the entire retort load requires efficient circulation, typically achieved through pumps or carefully engineered water flow. For manufacturers working with both traditional rigid containers and certain flexible formats, water immersion remains a reliable and proven choice.

Water Cascade Retorts

Water cascade retorts operate by pumping heated process water to the top of the vessel and allowing it to flow evenly over the containers through a specially designed distribution plate. This cascading action ensures consistent heating across the product load. For cylindrical containers, such as cans and bottles, this method is highly effective, as the shape allows water to distribute evenly.

However, for containers with perpendicular or flat surfaces, such as trays or pouches, there can be risks of uneven heating, where hot and cold spots develop. Advances in retort design have minimized these challenges, but manufacturers must carefully evaluate the geometry of their packaging before choosing this option. Despite these considerations, the water cascade system is favored in operations where cylindrical containers dominate production and where gentle handling of the load is important.

Steam/Air Retorts

Steam/air retorts are a more modern innovation, relying on high-speed fans to circulate a controlled mixture of steam and air within the chamber. This method creates a uniform heating environment while maintaining the pressure balance needed for flexible packaging. Because of their reliance on mechanical air circulation, steam/air retorts are particularly well-suited for flat or flexible containers such as pouches, shallow trays, and bowls, where direct steam contact alone would be insufficient or damaging.

Internationally, steam/air retorts are more commonly used than in the United States, but their relevance is growing as global packaging formats continue to evolve. They are especially valuable in markets that emphasize flexible packaging for ready-to-eat meals, baby food, and nutritionally sensitive products.

Steam/Water Spray Retorts

Steam/water spray retorts are among the most versatile systems available today. These retorts distribute process water in the form of sprays, which are dispersed turbulently throughout the retort load. This method ensures rapid heat transfer and uniform coverage, even across mixed container types. The versatility of steam/water spray retorts makes them suitable for nearly all packaging formats, including cans, bottles, trays, and pouches.

Because they can accommodate a wide variety of packaging geometries, these systems are often the choice for processors managing multiple product lines or constantly adapting to new packaging trends. The turbulent spray action also reduces processing times, which helps in preserving product quality while ensuring safety.

Selecting the Right Retort for Your Containers

The process of selecting the correct retort is not as simple as choosing the most advanced system on the market. Instead, it requires a careful analysis of both the container and the product characteristics. Each packaging format behaves differently under thermal stress, and a retort system must be chosen that balances sterility assurance with the preservation of quality.

Cylindrical containers such as cans, bottles, and jars are well matched with water immersion or water cascade systems. The consistent shape of these containers allows for predictable heating patterns, making these retorts a reliable choice. For manufacturers that continue to focus on traditional metal cans or glass jars, immersion or cascade systems are generally the best option.

Flat or flexible containers such as pouches, trays, and bowls demand a different approach. These packages require uniform heating across flat surfaces and seals, and they are also more vulnerable to deformation under high pressure. For these reasons, steam/air and steam/water spray retorts are better suited. Steam/air systems create a controlled environment for flat packages, while steam/water spray retorts offer greater versatility and can handle mixed loads.

For manufacturers who work with a combination of rigid and flexible packaging formats, versatility becomes the deciding factor. In these cases, steam/water spray systems often emerge as the most practical solution, as they can handle a wide spectrum of packaging geometries with consistent results.

It is also essential to consider the type of product being processed. Viscous or particulate foods, such as soups, sauces, or ready-to-eat curries, may benefit from systems that promote rapid heat penetration, while delicate products like baby food or nutritionally sensitive beverages require gentle but uniform thermal treatment. The choice of retort system should therefore align with both the container and the unique thermal properties of the product inside.

Conclusion

In today’s dynamic food industry, the decision to select the right retort system goes far beyond equipment choice—it is a strategic decision that impacts product safety, regulatory compliance, operational flexibility, and brand reputation.

For manufacturers of Acidified and Low-Acid Canned Foods, understanding the compatibility between container type, product formulation, and retort design is essential. Water immersion and water cascade retorts remain strong choices for cylindrical containers, while steam/air and steam/water spray retorts are better suited for modern flat and flexible packaging. Steam/water spray systems, in particular, stand out for their adaptability to diverse packaging formats.

By carefully aligning retort technology with packaging and product needs, manufacturers can ensure sterility, maintain high product quality, and build consumer trust. In a marketplace defined by innovation and evolving packaging demands, choosing the right retort system is a critical step toward long-term success.